D3E3 Anti Metal Splash Fabric:Fabric for protective clothing according to EN ISO 11612, EN ISO 11611 and EN 1149-5 after pre-treatment by domestic washing according to EN ISO 6330.

If you need timely service, please contact us through online chat on our website

or Email: inquiry@cgprotection.com

WhatsApp: +8617317656853

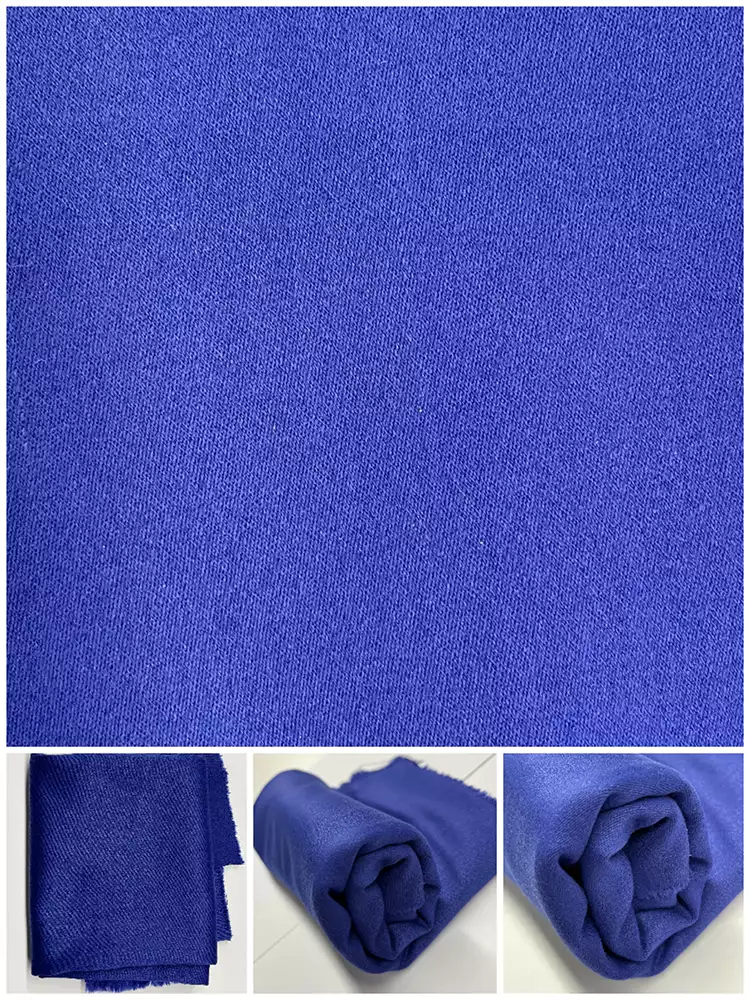

| Performance Features: | Satin weave structure: good wear resistance; wool blend for soft touch; multiple color options and customizable for customer colors; meets performance requirements for flame retardancy and metal splash protection, with EN11612 A1,B1,C1,D3,E3,F1 European standard test reports. |

| Supply Capacity: | Can produce 50,000-100,000 meters per month. |

| Colors: | navy blue and royal blue; customizable colors: can be customized according to customer requirements. |

| Application Scenarios: | Suitable for welding, smelting, casting, and working with molten metal splashes. |

| Standards: | EN11612 A1,B1,C1,D3,E3,F1. |

| Model: | CG-ML-01. |

| Minimum Order Quantity: | 1,000 meters. |

© 2023 Shanghai C&G. All Rights Reserved.