Instructions for use of Shanghai C&G Safety Co., Ltd. spray liquid-tight chemical protective clothing

Shanghai C&G Safety Co., Ltd. has a variety of chemical protective clothing, among which the spray liquid-tight chemical protective clothing, namely CG300B, is a popular one. Today we will introduce the instructions for use of this protective clothing.

1. Usage restrictions

1. Please select and confirm the protective clothing that suits your size before use.

2. Do not use if the packaging is damaged. Please visually inspect the protective clothing before wearing it. Do not wear it if it is damaged, discolored, or contaminated.

3. This product uses non-woven fabrics made of polymer materials and is made into a hooded one-piece structure. The foot, cuffs, waist and other positions are adjustable.

4. Flame resistant description: This protective clothing is non-flame resistant material.

5. Please read the instructions carefully before use.

6. The user should judge whether this product is suitable for a specific occasion. If the use occasion exceeds the purpose and use restrictions of this product, we do not make any guarantees for this and do not assume any responsibility related to this.

7. Please avoid direct sunlight.

8. Please keep away from heat sources and open flames when using. Do not use in heat sources, open flames, sparks or flammable or explosive environments.

9. This product only protects the part that covers the body.

10. The product is not suitable for use in high temperature or extremely low temperature environments.

11. Please make sure that all seams and closures are intact before use. Protective clothing that is damaged, damaged or contaminated cannot be used.

12. Wear clothes correctly according to the wearing and taking off operation procedures.

13. The structure of this product shall not be changed at will.

14. This product is a non- protective clothing and is not suitable for places with strict microbial index control such as isolation intensive care areas (rooms).

2. Implementation standards

GB 24539-2021 "Protective clothing Chemical protective clothing"

3. Product type

Type 3

4. Main technical indicators

1. Whole-piece liquid-tight spray: Type 3 Spray liquid-tight chemical protective clothing

2. Liquid pressure penetration performance: Level 6 (30% sodium hydroxide/methanol/acetonitrile>35kPa)

3. Abrasion resistance: Level 4 (900 laps damaged)

4. Flex failure resistance: Level 1 (>500 laps undamaged)

5. Tear strength: Level 3 (>40N)

6. Breaking strength: Level 2 (>60N)

7. Puncture resistance: Level 1 (>5N)

8. High temperature resistance: Breaking strength decreases by no more than 30%

9. Low temperature resistance: Breaking strength decreases by no more than 30%

10. Seam liquid pressure penetration performance: Level 6 (30% Sodium hydroxide/methanol/acetonitrile>35kPa)

11. Seam strength: Level 4 (>125N)

12. Permeability (seam performance/fabric performance): Level 3 (96% sulfuric acid/30% sodium hydroxide: t>60min)

V. Size specification

L(175)

VI. Validity period

Under normal use, the service life is 3 years. According to actual conditions, the period may be reduced as appropriate.

VII. Pre-use inspection procedure

1. Please read the instructions carefully before use.

2. It is recommended that a qualified person provide comprehensive training services on safe use and restrictions before use, and record the training details. Please refer to the instructions for wearing and taking off that come with the protective clothing.

3. Please select and confirm the protective clothing that suits your size before use.

4. Do not use if the packaging is damaged. Please visually inspect the protective clothing before wearing. Do not wear it if it is damaged, discolored, or contaminated.

5. Before use, please ensure that all seams and closures of the protective clothing are intact. If there is any damage, damage or contamination, the protective clothing cannot be used.

6. Please decide whether you need to wear other protective equipment according to your needs.

7. Please check the expiration date of the product before use. If it has exceeded the expiration date, do not use it.

8. Check whether the product protection level meets the type and concentration of chemicals in the working environment. If the product is defective, do not use it.

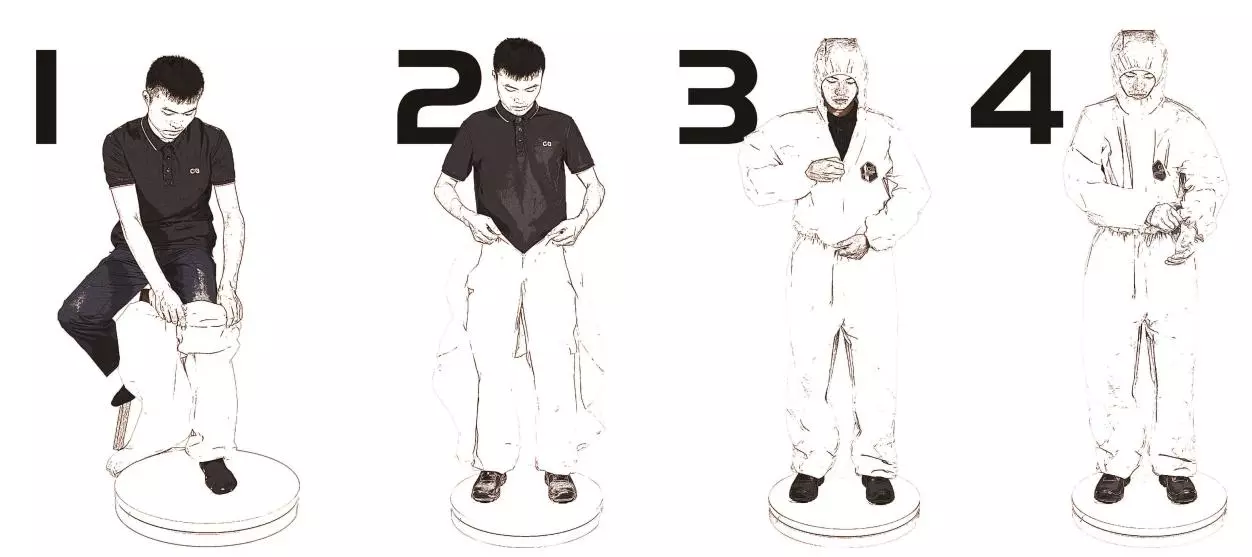

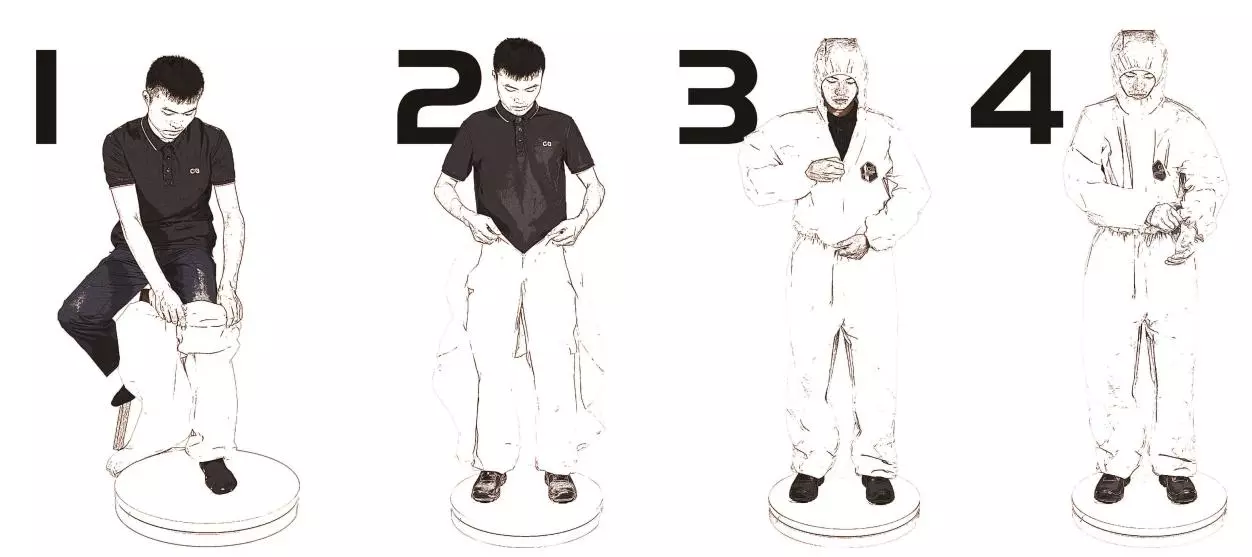

Putting on and taking off steps:

Please follow the steps below to put on chemical protective clothing:

1. Choose a clean place, unpack the product and take off your shoes. Zip up the protective clothing to the appropriate position.

2. Hold the protective clothing hood, sleeves and zipper opening with both hands at the same time to prevent the protective clothing from touching the ground.

3. Put on the lower body first, then the upper body. Put on other products for facial protection (such as masks, protective glasses), then put on the protective clothing hood, and finally pull the zipper to the top and stick the collar and placket double-sided tape.

4. Arrange the protective clothing and finally put on protective gloves.

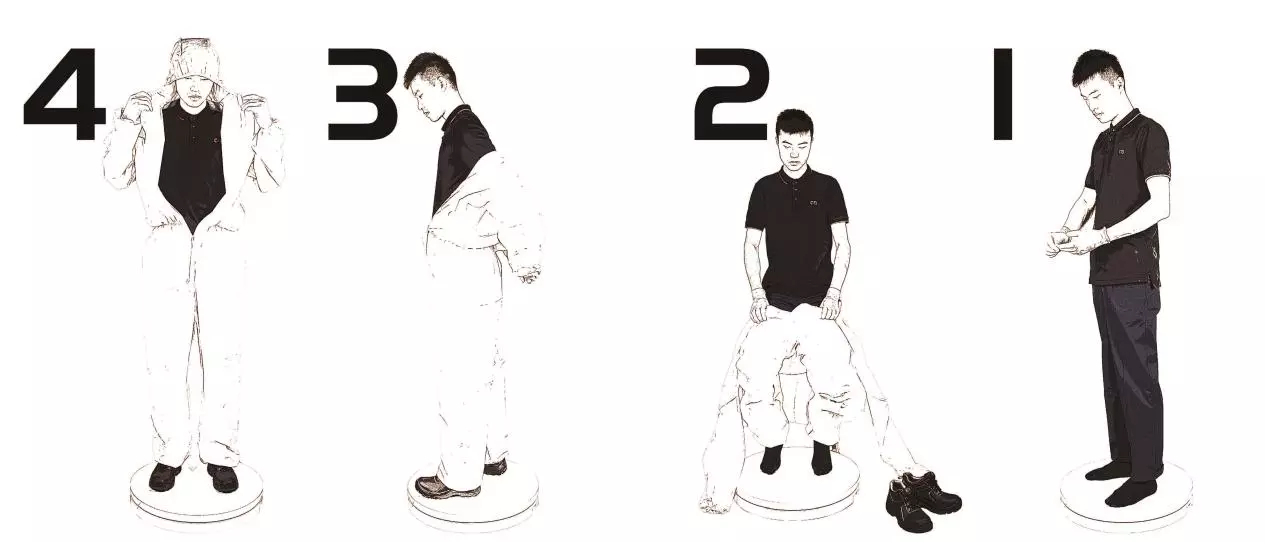

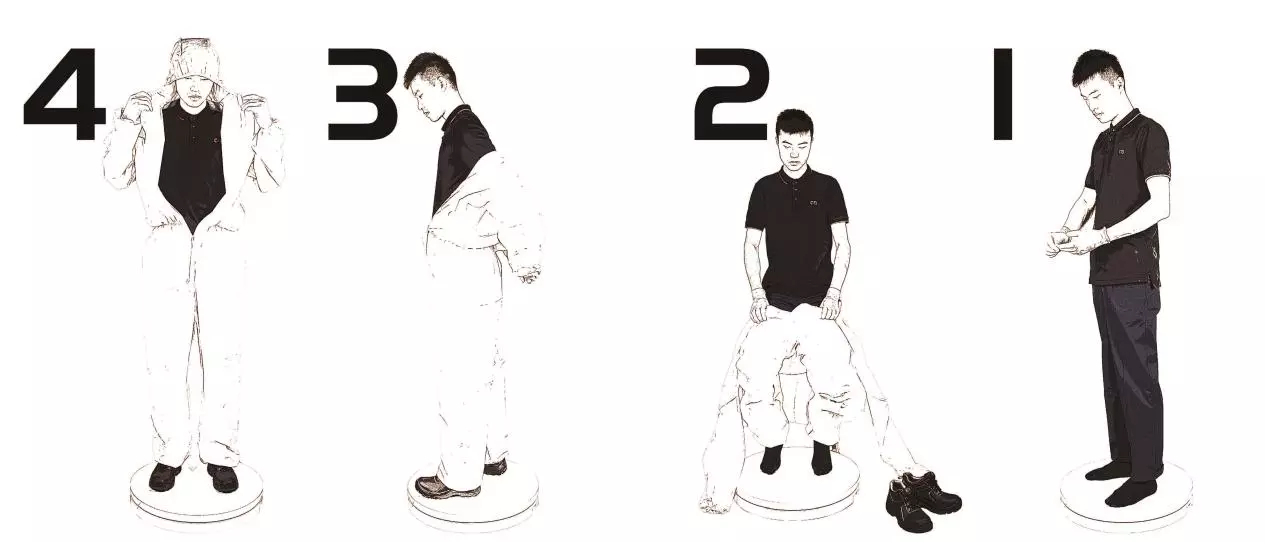

Please follow the steps below to remove the chemical protective clothing:

1. Tear off the double-sided tape on the collar, pull down the zipper, and take off the protective clothing hood.

2. Take off the cuffs and upper body of the protective clothing from the back.

3. After sitting down, take off your shoes first, and then take off the lower body of the protective clothing.

4. Do not discard contaminated protective clothing at will. Please properly dispose of contaminated protective clothing according to local regulations.

VIII. Care and maintenance information

The clothes cannot be washed, ironed, dry-cleaned, bleached, tumble-dried, exposed to the sun, and baked. Keep them dry.

IX. Invalidation and disposal suggestions

If you find that the clothes are worn, torn, or wetted by water and penetrate into the back of the clothes when wearing spray-tight chemical protective clothing, you should stop using them and judge them as scrap.

Abandoned work clothes should be properly handled and should not cause pollution to the environment.